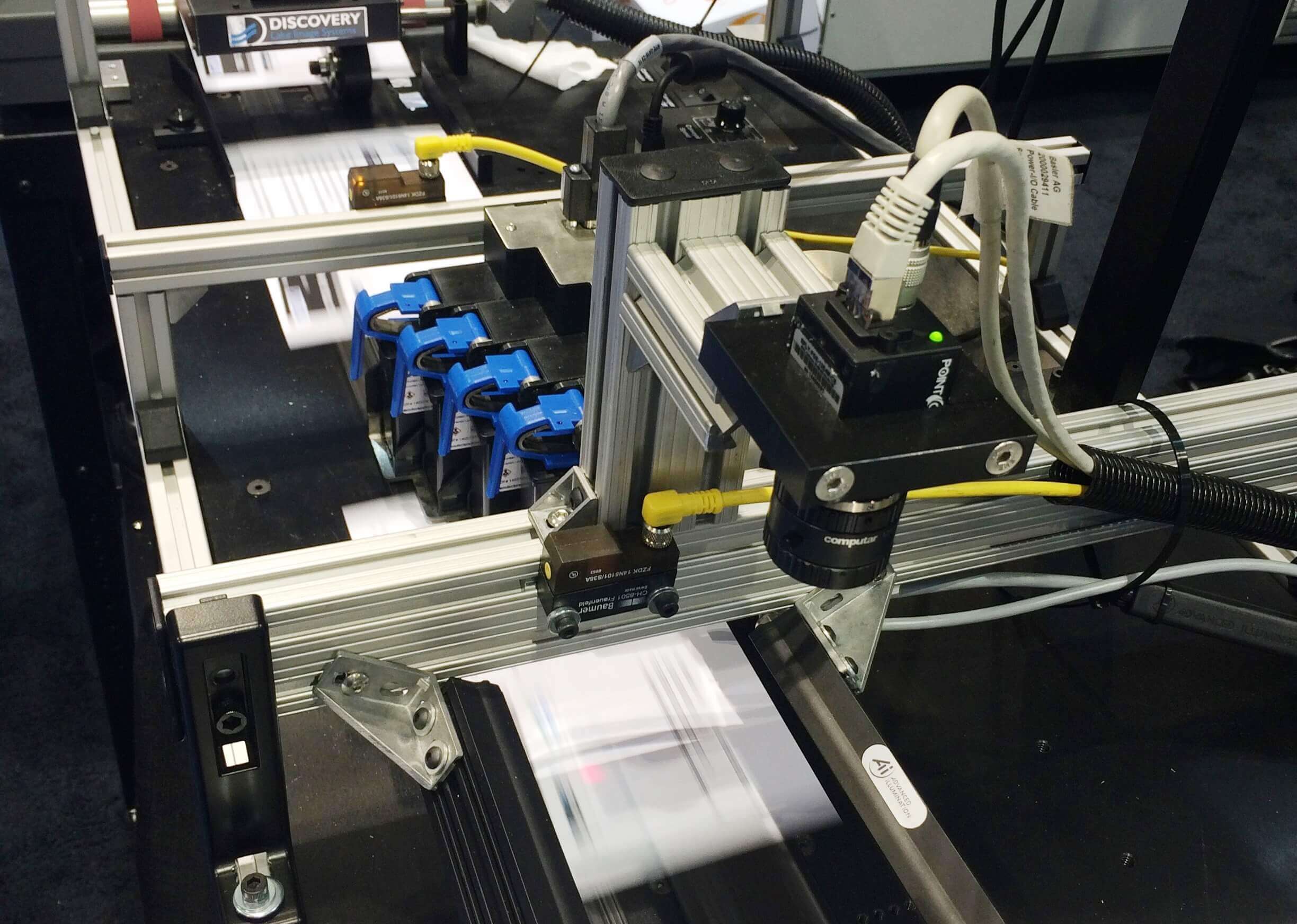

Lake Image DISCOVERY Bindery Inspection System —

Bindery departments experience problems such as incorrect page sequencing, missing/duplicate pages, and wrong page orientation are common. These issues can arise from operator errors or mechanical faults like misfeeds and jams, often exacerbated by poor environmental conditions (like static electricity, temperature, and humidity). Tracing and rectifying these issues is time-consuming and costly, requiring reconfiguration and setup of the processing steps.

Manual quality checks can identify major errors but are inadequate for detecting small or random errors. Since most equipment operates at high speeds and is heavily shielded for safety, it’s challenging for operators to detect errors during operation.

These finishing integrity errors can lead to operational inefficiencies, equipment bottlenecks, waste, missed delivery times, unsatisfied customers, and potential loss of business.

To address these challenges, DISCOVERY Bindery offers an automated integrity management system. It uses camera and scanner technologies to capture images/data, processed by DISCOVERY software tools for reading, controlling, inspecting, verifying, logging, and reporting. This ensures 100% finishing integrity verification and control, reducing the likelihood of errors and enhancing operational

Key Features —

- Sequencing, Missing and Duplicate Page Detection: DISCOVERY Bindery uses OCR and barcode reading tools to ensure the correct order of pages/signatures in booklets. It checks the correct base stock and tray during setup and verifies the page sequence, front and back matching, and page count during production. The system automatically alerts and halts production if there are any issues like wrong tray/stock loading, sequence errors, or missing/duplicate pages.

- Multi-Pocket Stock Verification: Modern booklet makers often have multiple pockets (up to 30) that need to be loaded correctly. The Pocket Trainer feature of DISCOVERY Bindery simplifies this process by taking and storing images from each pocket, which are then used as references during production to ensure correct loading. Errors in loading trigger a halt or diversion in the production line.

- Production Line Tracking, Logging, and Error Reporting: The system tracks production lines in real time, immediately identifying and reporting integrity errors. This feature helps in quickly pinpointing and correcting errors, thus minimizing downtime. A detailed audit file is maintained for each production, which can be exported for further analysis or integration with factory control systems.

Request more information on the Lake Image DISCOVERY Bindery Inspection System by clicking the blue button to the right. Or, view more info in the PDF brochure on the Resources tab.

Click here to view Lake Image’ Partners Page for more information on the brand & their equipment!

-

Machine 1

-

Machine 2

-

Machine 3