-

Max. Sheet Size

500 x 700 mm | 19.69” x 27.56”

-

Min. Sheet Size

80 x 100 mm | 3.15” x 3.94”

-

Sheet Weight

80 to 600 gsm | 60 lbs. to 40 pt

-

Min. Creasing Distance

0.1 mm

-

Max. Speed

233 sheets per minute

-

Net Weight

580 lbs.

-

Machine Dimensions

5.9' L x 3.0' W x 3.9' H

Bacciottini PIT STOP D2H High Speed Creasing, Perforating, & Punching Machine –

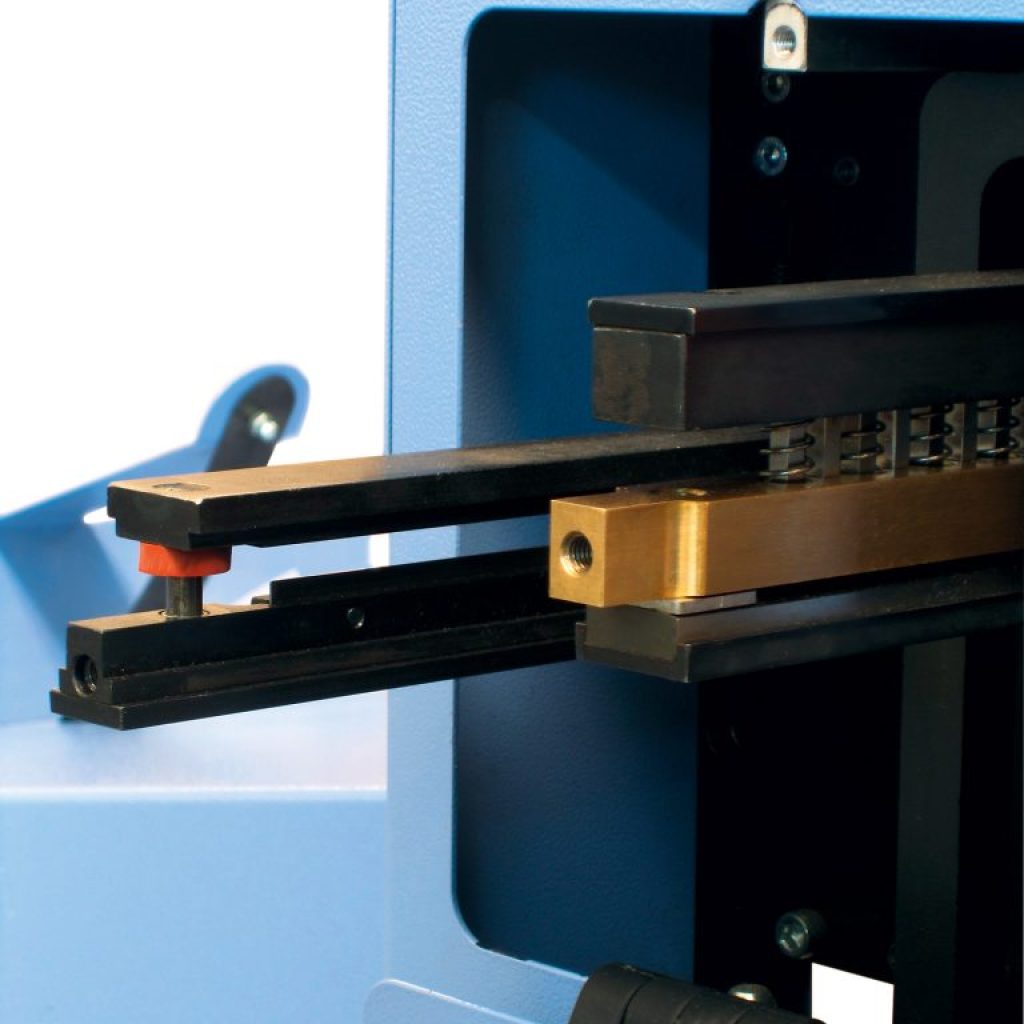

The PIT STOP D2H High Speed has the same specifications as the PIT STOP FM with the addition of a second head. The second head is in parallel to the first one with the tool operating from the bottom rather than the top. this enables creasing to be done in the same pass or by fitting two creasing tools. Creasing can be done from the top and bottom in the same pass ensuring the correct crease direction for zig zag folding.

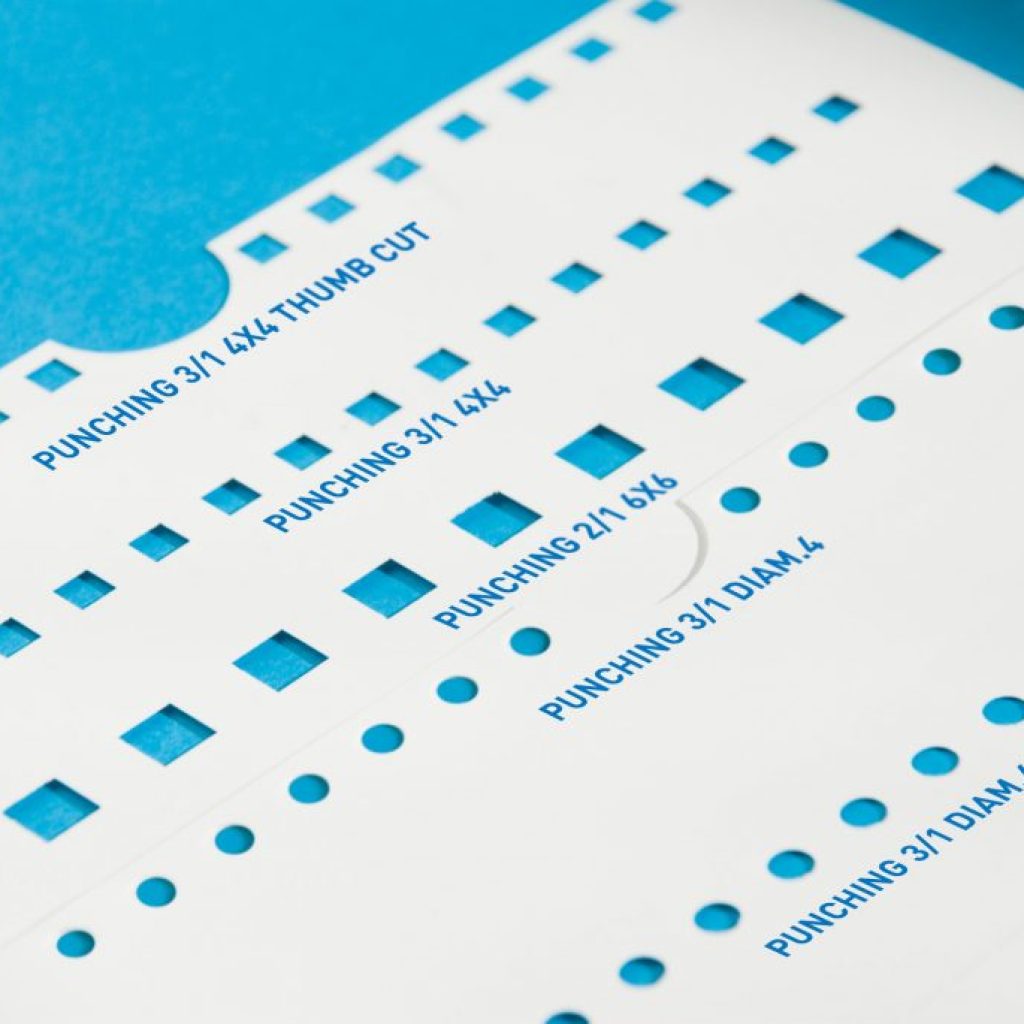

Capabilities:

- Creasing

- Digital Creasing

- Perforation

- Micro Perforation

- Punching

Bacciottini products are equipped with touch screens to input sheet size, thickness, and crease details — allowing easy job setup. Optional software automates this by allowing front office staff to input job parameters. A unique QR code encapsulates the information, ensuring accuracy in production. Workers use a scanning gun attached to the production machine, similar to self-checkout devices in stores, to read the QR code. The machine configures itself automatically, eliminating manual adjustments and human error. This integration of technology streamlines the workflow, reducing time and effort, and ensures a smooth, error-free process. Click here to read more!

Request more information on the Bacciottini PIT STOP D2H High Speed Creasing, Perforating, & Punching Machine by clicking the blue button to the right. Or, view more info in the PDF brochure on the Resources tab.

Founded in 1983, Bacciottini Group is a leading company in engineering and manufacturing completely automated machines to perform creasing, folding, perforating, and punching functions. Bacciottini products are globally recognized and appreciated for quality, efficiency, long-life, and ease of use. 5,000 of these units have been installed world-wide, with many still in production 20 years later.

-

Machine 1

-

Machine 2

-

Machine 3