-

Cycle Speed

15,000

-

Max. Size Format

605 x 750mm | 23.82" x 29.53"

-

Min. Size Format

210 x 350 mm | 8.27" x 13.78"

-

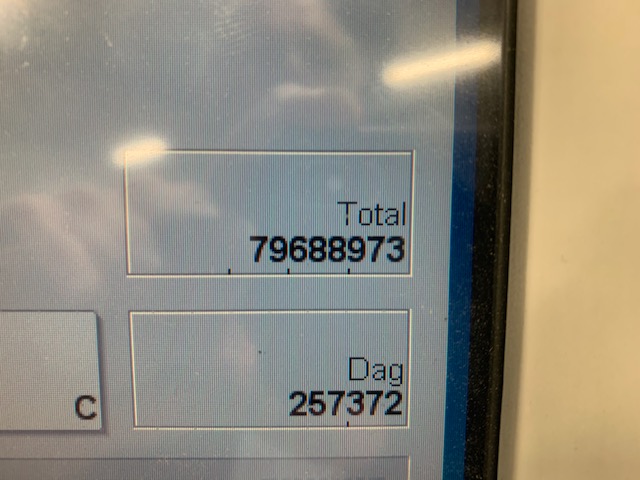

Count

80 Million

-

Status

Available

-

Availability

Immediately

2010 Heidelberg XL 75-6+LX3 (F format) Only 80 million impressions

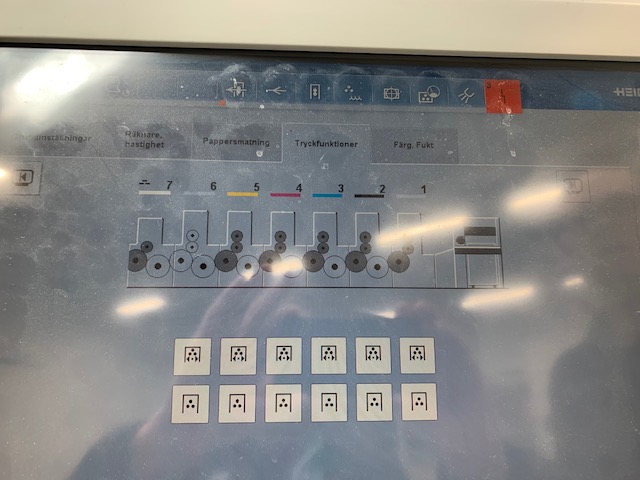

- Instant gate – Inkprofiles from prepress, from another Speedmaster, and

Plate on demand automatic plate from PressCenter ( Only to HBG Rip )

- HOST Interface

- Interface for Pressroom Manager – Working information from the Printing machine with Exented cables to computer system PressCenter

- Steel plate in Feeder & Delivery

- 2 UV Interdeck dryer CANopen, water cooled, 200 W/cm with Stepless Lamp Control ( SLC ) Quick Change of lamps ( FLC ), URS reflectors

- Interdeck Docking stations all Print Units

- Automatic impression cylinder Washers for UV-Ink

- Automatic Blanket washers for Combination conventional and UV-Ink

- Combination UV Dampening form Rollers all print units

- COMBISTAR CANopen Combination Ink and dampening temperature controls water cooled with Alcohol meter and mixture control

- Combination rollers for conventional and UV INK

- WASH-UP & Go System for simple Ink fountain cleaning

- DRYSTAR Combination UV, CANopen End Dryer for UV and conventional INK and Laquer, Water Cooled, IR/HOT AIR Cassette, 1 UV Cassette with 3 Lamps 200W/cm with Stepless Lamp control, URS-reflector,s and FLC , Quick change Lamps, and chilled sheet Guides in delivery

- Exented Delivery X3 240 cm

- PowderStar AP 262 powderspray CANopen

- UV Prepared Delivery

- AXISCONTROL spectro integrated PressCenter

- Chambered Doctor Blade COATING UNI with Extra Chamber for UV Coating, 1 Anilox roller (120 lines ) + 1 Extra anilox roller, Two Coating pumps with 550 liter capacity for Aqueous coating + one for UV Coating

- Antistatic equipment SPECIAL KIT for printing PLASTICS and FOIL for Feeder and Delivery

- AIRSTAR compressor with low energy consumption technology, Water Cooled

- Oil Pan under Printing machine

- Ink Mixer for UV-INK

- INSTANTSTART fast startup of UV DRYER

- TECHNOTRANS BETA F Water cleaning System

- Machine Transport Packing includes Pallets

- Possible to add one additional INTERDECK Dryer (Prepared in Cabinet)

- AZTOGRAPH AZTO – LVA40

- INKSTAR with AGITATORS unit 1 – 4

-

Machine 1

-

Machine 2

-

Machine 3