-

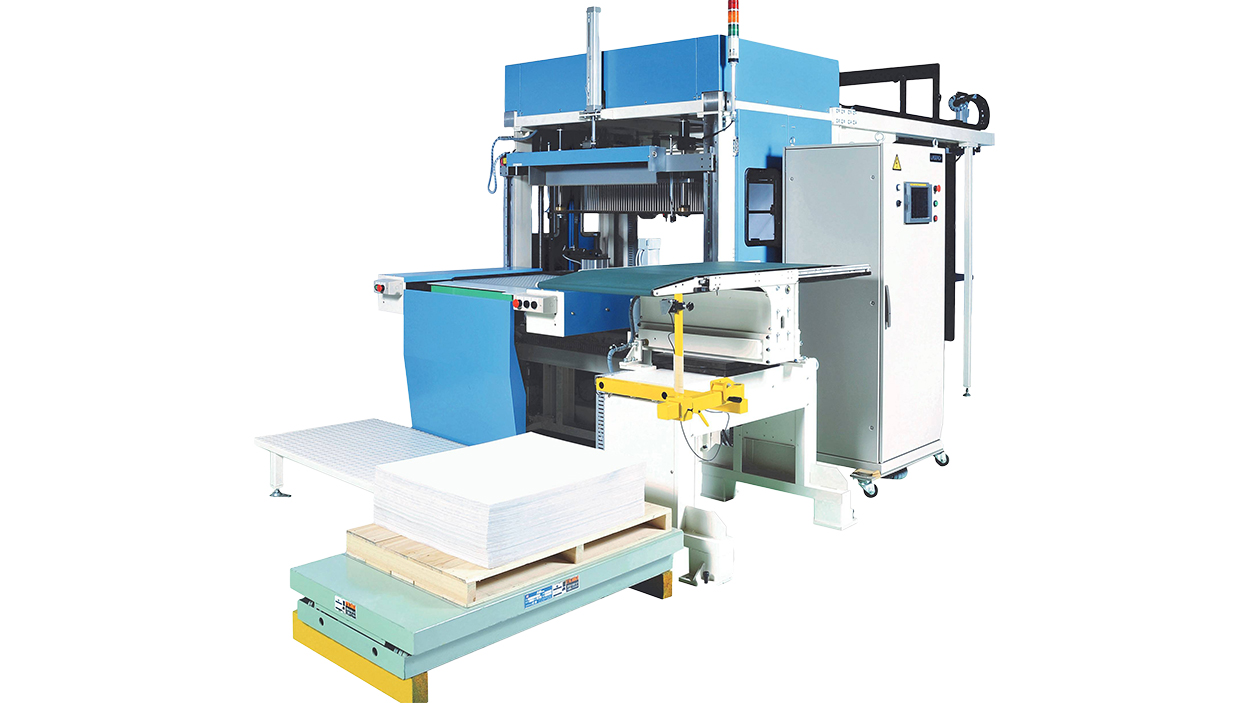

Main Unit Size

6.56' W x 8.95' D x 8.69' H

-

Main Unit Weight

Approx. 2,800 kg | 6,160 Lbs.

-

Max. Sheet Size*

31.5" x 43.3" | 800 mm x 1100 mm

-

*Optional: 43" x 57”

-

Min. Sheet Size

15.75" x 15.75" | 400 mm x 400 mm

-

Mechanical Speed

9,000 - 12,000 sheets/hour

-

Pallets Per Hour

Approx. 5.4 Pallets

-

Single Cycle Time

55 Seconds

-

Min. Spacing Between Blanks

0 - 10 mm (Depending on Layout of the Sheet)

-

Max. Lift per Cycle

80mm | 3.1"

-

Max. Pile Height at Delivery

1,400 mm | 55"

-

Number of Pins

3,391 Upper; 1,333 Lower

-

Power Requirements

3-Phase, 200 V, 60 A

Laserck Master Blanker BLK Offline Blanker —

- Master Blanker does not require male/female blanking tools, reducing costs as well as allowing for faster changeovers

- Operated by a single person rather than multiple people stripping the pile by hand

- Features a template system that organizes the upper and lower pins using paperboard, ultimately using CAD software to create blanking templates utilized within the Laserck BLK Offline Blanker

- Changeovers can be accomplished in about 5 minutes!

- Includes an automated rotating conveyor, reducing labor for the operator, and increases efficiency

- Includes Automatic Palletizer after blanking, which transfers the blanks to the pallet

- Optional Lateral Conveyor for “Hard to Stack” – I.E., IML Labels – products (View YouTube link here)

Request more information on the Laserck Master Blanker BLK Offline Blanker by clicking the blue button to the right. Or, view more info in the PDF brochure on the Resources tab.

Laserck, headquartered in Osaka, Japan, has been the premier supplier of Offline Blanking in Japan and Southeast Asia for over 35 years. With their highly patented design, Laserck has over 100 Offline Blanking systems installed worldwide.

Click here to view Laserck’s Partners Page for more information on the brand & their equipment!