-

Max. Size Format

-

— BL

220 x 260 mm | 8.66" x " 10.24"

-

— BLS

230 x 320 mm | 9.06" x " 12.60"

-

Min. Size Format

-

— BL

15 x 15 mm | 0.59" x 0.59"

-

— BLS

20 x 20 mm | 0.79" x 0.79"

-

Max. Stack Height

190 mm | 7.48"

-

Punching Pressure

12,600 lbs

-

Punching Strokes

-

— BL

18 per minute

-

— BLS

16 per minute

-

Max. Machine Output

-

— BL

1,080,000 sph

-

— BLS

960,000 sph

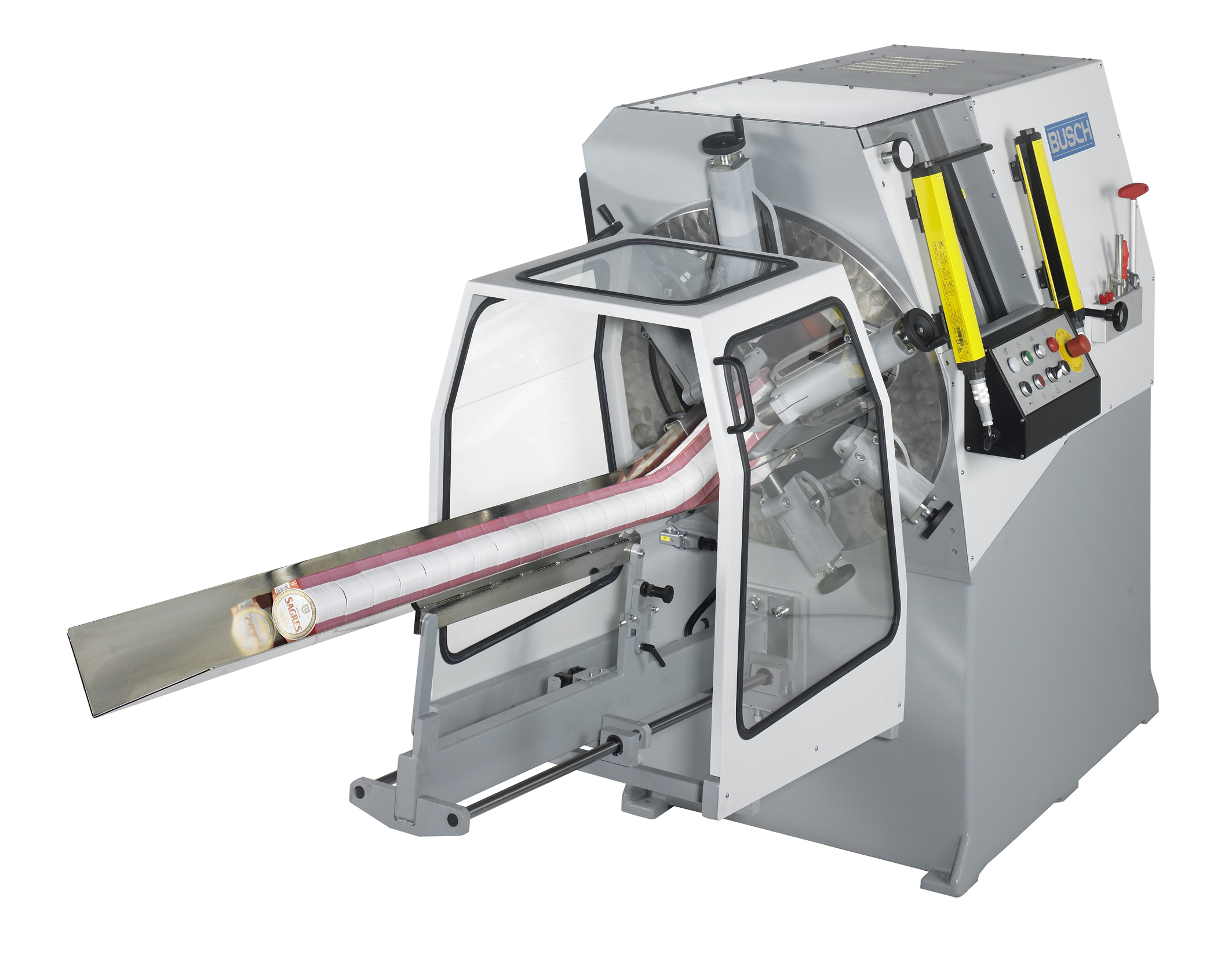

Busch BL / BLS High Die Cutter —

The BL / BLS High Die Cutters are engineered for enhanced productivity in processing larger formats. Equipped with sophisticated light barrier technology for cutting stroke activation, these machines are tailored for medium to large-scale operations, capable of handling a diverse range of materials and articles. The BL model supports a maximum cutting size of 220 x 260 mm, while the BLS model extends capabilities to 230 x 320 mm, showcasing their aptitude for larger tasks.

The sturdy design of these machines is a testament to their increased punching power, with hydraulic equipment seamlessly integrated within the body. Despite their identical construction and functionality, the models differ in body size to accommodate the varying cutting dimensions.

Each machine comes equipped with adjustable clamping arms (5 for BL, 6 for BLS), alongside waste slitters and holders that can be optimally positioned for precise waste management. The configuration is designed to adapt to the material, size, and shape of the product being die cut.

Accessibility is further improved with a sliding door at the rear, simplifying the installation of dies and waste slitters and providing dual-sided access to the cutting section.

These High Die Cutters excel in producing intricate contours for large-sized labels, brochures, children’s booklets, credit and loyalty cards, and special material for in-mould labels, among others. They are ideal for high-volume processing across a broad spectrum of products.

The BL / BLS High Die Cutters feature an innovative light barrier system for activating the cutting stroke, ensuring precision and safety. Upon inserting the material stack and retracting the hands from the punching area, the cutting stroke is automatically initiated, halting immediately if the light barrier is breached during operation.

Both models can be easily outfitted with a counter-pressure unit in lieu of the delivery tray, with a trolley aiding in the swift exchange and storage of the tray for non-counter-pressure tasks. This adaptation takes roughly 20 minutes, significantly diversifying the machine’s application range.

The dies are specifically crafted for counter-pressure cutting, incorporating a movable matrix to secure and stabilize the material during the hydraulic cut. This process culminates with the finished material being smoothly transitioned back into the feeding tray by a pneumatic cylinder, though it does halve the machine’s throughput.

The counter-pressure device is recommended for intricate tasks, such as die-cutting embossed paper and plastics (PP or PE foil) for in-mould labels, cutting tempered and varnished aluminium foil, processing large-sized labels from challenging materials, executing 4-sided cuts on folded sheets, and applications requiring stringent tolerances. This enhancement is crucial for maintaining precision and minimizing material distortion during the cutting process.

Request more information on the Busch BL / BLS High Die Cutter by clicking the blue button to the right. Or, view more info in the PDF brochure on the Resources tab.

Located in Hamburg, Germany, Busch has specialized in the production of Pile Turners, Banders, Waste Conveyors, and High Die Cutters for over four decades. Globally, over 15,000 Busch machines have been installed, with Best Graphics successfully selling more than 250 of these innovative machines.

Click here to view Busch’s Partners Page for more information on the brand & their equipment!

-

Machine 1

-

Machine 2

-

Machine 3