Best Graphics Hosts Clients at Chameleon Finishing Solutions Facilities

01.31.2014

This week, Best Graphics had the pleasure of hosting clients from Long Island, Illinois, and Florida at our vendor partner’s facilities. Chameleon Finishing Solutions, manufactured in the U.S.A,, has been producing creative solutions for the Packaging and Mailing worlds for nearly six years.

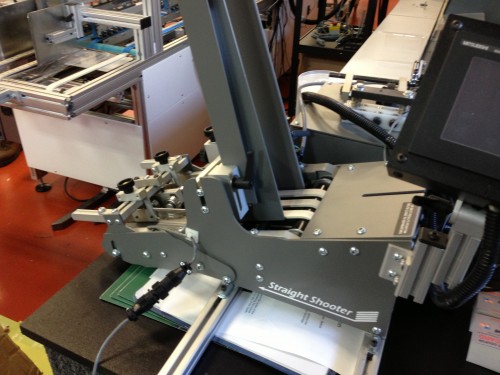

Located in Rochester, NY, Chameleon produces a line of Folder Gluers that were born in the Packging world, but have brought fresh ideas to the world of Direct Mail production. Modular in design, with a small footprint in mind, Chameleon systems are ideal for Commercial Printers who are looking to capture traditional Presentation Folders, Gusseted Pocket Folders, CD Sleeves, 3-Panel and 5-Panel Direct Mail applications, Tipping/Affixing work, Promotional Products, and Folded Carton jobs.

Chameleon Gluers are designed, engineered, manufactured, and assembled at their facilities in Rochester, NY. Owned by Joe Marrinan, Chameleon Finishing Solutions, shares warehouse space with their sister company, a manufacturing tool & die shop.

Here’s Joe, alongside Dan Brahm, President of Best Graphics, and our clients, “kickin’ the tires” on one of the four Chameleon Gluers that were on display, and in production, this week!

Have you outgrown your Kluge, or Moll, “Legacy Gluer?” Do you frequently pass on bids because your equipment can’t achieve the speeds and flexibility to run both Carton and Mailing jobs? Sick and tired of re-doing make-readies after every machine jam? Frustrated by the limitations of where your “Legacy Gluer” can cross, and plow, fold? Have you ever wondered how in the hell they do those “Iron Crosses!?” Look no further, the Chameleon Line of economically prices Gluers is the innovative solution for you!

Do you prefer hot melt, or cold, glue? Do you need a machine in 25″, 31.5″ or 36″ in working width? Do you prefer a machine with 7 feet of transport section, or 15 feet!? Are you in need of friction fed Feeders to Tip/Affix product, or do you need Pack Smart Feeders for uniquely shaped P.I.s requiring tighter registration?

Could you use an extra Crossfold Plate, or would you prefer “Bump Turning” product 90 & 180 degrees? Would you like an inline Score/Perf module at the Pre-Feed, or do you want a heavy Compression Delivery for the extra tough substrates?

No need to worry! Chameleon can provide you with all! Every system is unique! No two machines are assembled the same! Call it “Carte Blanche,” ’cause it’s supper time baby, and everything on the menu is available! So, let’s recap. Does the idea of a Chameleon make sense? Of Course! Benefits we see as advantageous for our clients: 1) Small Footprint – Space constraints are an issue for every shop 2) Wider Scope of Machine Capabilities – Pocket Folders, Mailers, Bump Turns, Tipping/Affixing Cards, etc. 3) Faster Speeds – Clients have run product in excess of 90k an hour (!) . . . 4) Shorter Makereadies – The “Bridge & Beam” design allows for quick access to the Plows placed in infinitely adjustable positions 5) Less Machine Downtime – Due to Chameleon’s Continuous Top Load Feeder (vs. a “Legacy” Gluer’s Pile Feeder) So what are you waiting for? Give us a call and schedule your demo today? Can’t break away to see the machines in action? No problem! Send us samples, we’ll run them for you, and ship ’em back! In the meantime, take a moment to review our Model 800MXX in greater detail via our www.BestGraphics.netweb listing:

Chameleon 31.5″ Model 800MXX Folder/Gluer

Within the listing you’ll see video of the machine running. Interested in seeing more videos? We have a whole slew of them! Give us a call, we’ll be happy to send you more: (800) 236-7603. Ask for me, A.J. Brahm! Enjoy the Super Bowl weekend, guys! And if you’re from the Midwest, like us, or the Upper Northeast, like our Chameleon partners, be sure to bundle up & stay warm!

– A.J. Brahm, Self-Appointed Chief Social Media Officer