Leading U.S. Healthcare Provider Chooses Best Graphics’ Ibis Smart Binder for Variable Page Stitching

05.4.2020

Best Graphics’s Ibis Smart Binder Machine Selected to Produce Healthcare Company’s Variable Data Printed Booklets –

Best Graphics, the North American distributor for Ibis Smart Binders, has secured a new “Smart Binder 3” order from one of North America’s most prominent healthcare organizations. This Smart Binder will be able to wire stitch (SB 2), or spine glue (SB 3) booklets depending upon the client’s preference.

Ibis, manufactured in the U.K., is a market leader in the world of high-speed variable data, variable page count saddle stitching. Founded more than 20-years ago by John Cracknell, Best Graphics has been Ibis’ U.S. and Canadian distributor for the last 3-years.

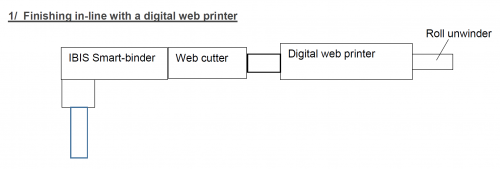

For this particular project, the Ibis will run inline. Paper will be unwound, from a roll, into a Canon digital print engine where critical, and highly personalized, medical information will be inkjet printed. The use of 2D and 3D barcodes will allow the Smart Binder to intelligently track each patient’s information downstream.

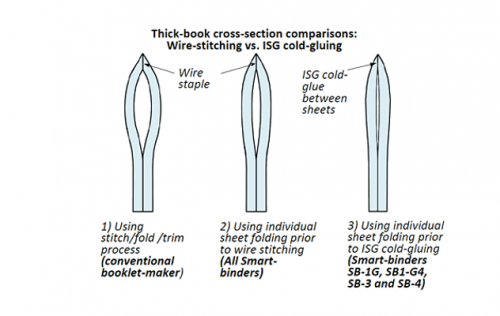

After exiting the Canon inkjet press, the continuous web of paper will be cut into 4-page sheets via a Tecnau digital finishing system. Thereafter, the 4-page sheets will be individually scored via the Ibis. By scoring each 4-page sheet the books will lay flatter (than the competition). A series of cameras and data tracking technology, from the Ibis Smart Binder 3, identify the number of 4-page sheets needed per book for each patient. Continuously collecting 4-page sheets atop one another, once “confirmed” by the Smart Binder, a collated set is released from the infeed of the Smart Binder and a cover — personalized, or static — is dropped atop the booklet. Thereafter, wire staples are stitched on the spine in advance of the booklet being three-knife trimmed. As an example, the healthcare providers’ booklets may complete in the following sequence without any stopping the machine: 8-page booklet, 12-page, 12-page, 16-page, 8-page, 24-page, 36-page, 32-page, 8-page, etc.

In the event a run of booklets wants to omit metal staples, the Smart Binder can produce spine glued books via our patented ISG cold glue technology. In this production sequence, each 4-page sheet passing through the Ibis Smart Binder 3 receives a row of glue dots. As each 4-page nests atop one another a booklet are formed. The use of the patented cold glue technology creates a). an elevated appearance in relation to wire staples, b). a higher page pull strength than wire stapled booklets, and c). allows the booklets to lay flatter and therefore insert easier, during the collation-mail insertion process.

Best Graphics’ Service Department will support this Ibis Smart Binder HS 3 model with delivery, installation, operator training, and an extended warranty. This Ibis will be one of nearly 100 Ibis machines sold into the North American market, making Ibis the U.S. leader in variable data, variable page Saddle Stitching.

Interested in taking your client’s personalized data to new levels? Ask Best Graphics about high-speed, digital booklet-making We’d be happy to help. Submit an online form to have one of our Sales Representatives assist you with the purchase of your next Saddle Stitching machinery.